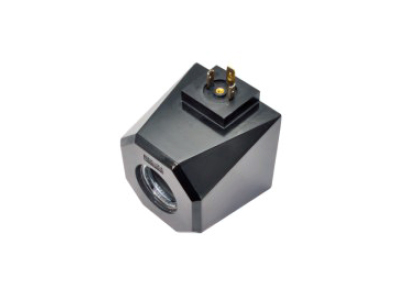

Ningbo Yinzhou TONLY Hydraulic Electrical Factory was established in 1989, which is a professional manufacturer of various On/Off and proportional solenoids for hydraulics. The factory is 10000m2. Thereinto, architecture covers 7000m2. As a famous China Other Solenoid Valve Coil Manufacturers and Other Solenoid Valve Coil Suppliers, the factory owns advanced high-precision CNC lathes, an automatic stitch welding machine, a BMC plastic package machine controlled by PLC, a plastic injection molding machine, a solenoid features tester, a solenoid tube oil-pressure-resistant test stand, a solenoid tube pulse fatigue test stand, an excitation coil parameters, and other testers. Through importing, absorbing, and technical upgrading. At present, we have an annual production capacity of 2,4 million pieces of hydraulic solenoids. All the products are produced according to JB/T5244-2001, VDE0580 standard and satisfy international advanced technical requirements. The performance is reliable and the quality is steady. Matched with Huade type, Northman type, YUKEN type, and VICKERS type, the products can be widely applied in machine tools, plastics machinery, engineering, aerospace, automotive, post and telecommunications, etc. The products are sold to the mainland, United States, Sweden, Korea, Taiwan, and other countries and regions.

How does the Proportional Solenoid for Hydraulics contribute to energy savings in hydraulic systems?

The Proportional Solenoid for Hydraulics is designed to provide fine-tuned regulation of fluid flow and pressure, which directly contributes...

READ MORE

English

English 简体中文

简体中文