1. Explosion Proof Solenoids for Hydraulics: Definition and Features

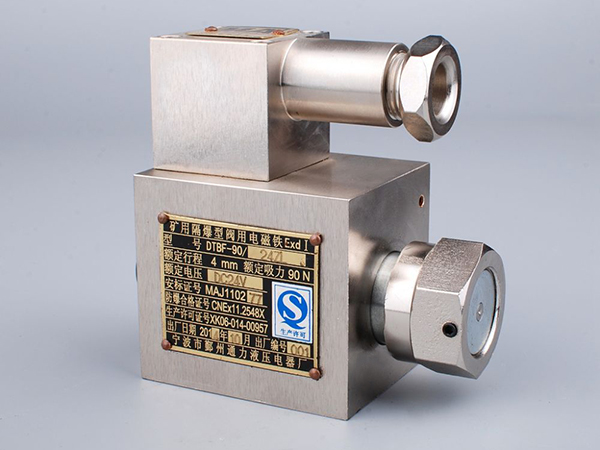

Explosion Proof Solenoids, or explosion-proof solenoid valves, are an integral part of hydraulic systems, especially in workplaces with flammable and explosive environments. The special design of these solenoid valves allows them to work safely and reliably under extreme conditions, preventing potential dangers caused by sparks or high temperatures.

Explosion-proof solenoid valves are designed with safety in mind. Their housings are made of explosion-proof materials, which can withstand the explosion pressure that may be generated inside, while preventing sparks or flames from leaking from the outside, ensuring the safe operation of the entire system. This special design is particularly important in high-risk industries such as petroleum, chemical, and coal mining.

Explosion-proof solenoid valves have efficient sealing performance. Using high-performance sealing materials and technology, these solenoid valves can completely isolate the medium in the closed state to avoid leakage. This not only helps to maintain the stable operation of the system, but also prevents the medium from polluting the environment.

Explosion-proof solenoid valves have extremely fast response speeds. After receiving the control signal, they can respond quickly to achieve rapid disconnection or connection of the medium. This fast response capability is essential to ensure the stability and safety of the system.

2. Application of Explosion Proof Solenoids in the Hydraulic Industry

Explosion Proof Solenoids are widely used in the hydraulic industry, covering many fields that require high safety and reliability.

In the petrochemical industry, flammable and explosive media make the production environment extremely dangerous. The application of explosion-proof solenoid valves provides important safety guarantees for these industries. They are used to control the flow of media in various hydraulic equipment and pipelines to ensure the stability and safety of the production process. For example, in the transportation system of an oil refinery, explosion-proof solenoid valves can ensure the smooth transportation of crude oil and refined oil while preventing leakage and fire accidents.

In coal mining, explosion-proof solenoid valves also play an important role. Due to the harsh environment of coal mines and the presence of a large amount of flammable gases and dust, explosion-proof solenoid valves are needed to control the hydraulic equipment of ventilation, drainage, transportation and other systems. The application of these solenoid valves not only improves production efficiency, but also ensures the life safety of miners.

In the metallurgical industry, high-temperature and high-pressure smelting processes are often accompanied by a large amount of flammable gases and dust. Explosion-proof solenoid valves are used to control the hydraulic system of smelting equipment to ensure the safety and efficiency of the smelting process. In the hydraulic control system of the iron-making blast furnace, the explosion-proof solenoid valve can realize the control of key actions such as furnace top charging and furnace door lifting, providing stable hydraulic power for the smelting process.

3. The importance and future trends of Explosion Proof Solenoids for Hydraulics

As the industrial field has higher and higher requirements for safe production, the importance of Explosion Proof Solenoids in the hydraulic industry has become increasingly prominent. They can not only ensure the safety of equipment and operators, but also improve production efficiency and reduce maintenance costs.

In the future, with the advancement of science and technology and the development of industry, Explosion Proof Solenoids will develop in a more intelligent, efficient and environmentally friendly direction. By introducing advanced control algorithms and sensor technology, remote monitoring and intelligent adjustment of solenoid valves can be achieved. This will make operation more convenient and flexible, and can also reduce failure rates and maintenance costs.

Environmental protection and sustainable development are also important trends in future development. Using more environmentally friendly materials and processes to manufacture explosion-proof solenoid valves and reduce energy consumption and waste emissions in the production process will be an important direction for future development. At the same time, optimizing the design and manufacturing process and improving the performance and reliability of solenoid valves are also the key to achieving sustainable development.

English

English 简体中文

简体中文